PXI Instrumentation for Partial Discharge Monitoring of Hydro Generators

- Aug 24, 2023

- 3 min read

Updated: Mar 30

The Challenge

Cepel needed to implement an online partial discharge (PD) monitoring and analysis system for hydroelectric power plant generators to aid the predictive diagnosis of stator electric insulation.

The Solution

Cepel developed a modular instrumentation system (IMA-DP) for online monitoring of PD in hydro generators using PXI hardware instrumentation from NI and signal processing algorithms implemented with LabVIEW. The company has adopted the system as an effective predictive maintenance tool.

Introduction

The Brazilian Electric Energy Research Center (Cepel), considered the largest electric energy research center in the Southern Hemisphere, has engaged in research and development for more than 40 years. Our efforts are focused on generation, transmission, and distribution of electric power. The Department of Transmission Lines and Electrical Equipment supports the maintenance engineering teams of various companies, trains professionals, and develops new technologies for predictive diagnosis and equipment prognosis.

Generators are prominent among other electrical system equipment and continuous monitoring is recommended. In the 1990s, we began developing the Asset Oriented Monitoring System (SOMA) for online monitoring of mechanical, thermal, and operational parameters in rotary machines. We adopted the PXI platform due to the ruggedness, flexibility, and modularity requirements of the DAQ hardware. However, to keep up with other state-of-the-art equipment, there was still a demand for monitoring the stator insulation of generators.

Left: PXI used to measure Partial Discharge or hydroelectric generators. Center: LabVIEW User Interface,

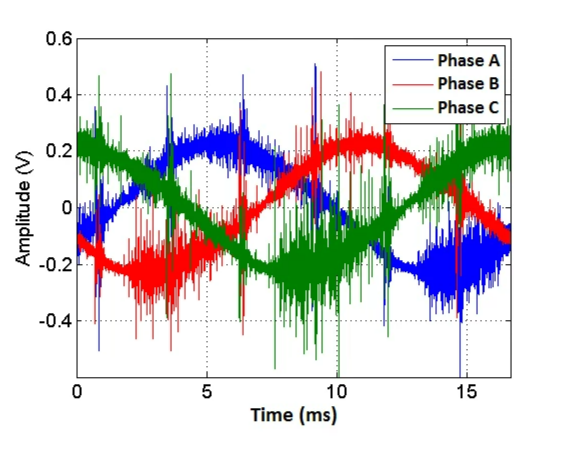

Right: Measured Signals

Electrical insulation has always been the weak spot of any high-voltage equipment. In addition to failures in maintenance and possible contingent events, the equipment’s own normal duty cycle causes insulation materials subject to vibration and thermal cycling to age and lose their dielectric properties. It is therefore necessary to assess the health of the insulation in such equipment with a view to the continuity of power supply and to the reduction of failures.

Partial discharge (PD) monitoring is an effective way to assess insulation integrity in high-voltage electrical equipment. In relation to other techniques traditionally recommended for monitoring insulation in rotary machines, PD measurement presents the highest sensitivity, permits the localization of defects, and is the only technique that can monitor generators online. Theoretically, PD measurement could have detected the estimated 89 percent of failures that occurred in insulation.

To meet the demand for online monitoring of stator insulation in rotary machines, we needed to implement an effective online PD monitoring system that was also compatible with the previously adopted generator monitoring hardware platform using the PXI instrumentation standard and taking advantage of its flexibility and modularity.

Measurement Features

PDs are localized dielectric breakdowns of a small portion of a solid or fluid electrical insulation system under high voltage stress, which does not bridge the space between two conductors. They occur in regions of gaseous insertions that represent imperfections in the dielectric (Figure 1). A PD can indicate defects that may evolve into insulation failures with serious consequences.

PD signals are pulses with frequency components that can reach hundreds of MHz, stochastic by nature, with variable amplitude, and heavily immersed in noise (Figure 2). The acquired pulses must have amplitudes recorded and be correlated with the phase of the voltage cycle. The products of the measurement are two-dimensional histograms, in which the repetition rate of the pulses is grouped as a function of their amplitudes and the phase angle (Figure 3).

Block Diagram of a Digital PD Measurement System

IMA-DP

Digital PD measurement systems comprise digital signal processing (DSP) units implemented in an FPGA and in conventional processors, with some additional signal conditioning circuits and A/D converters (Figure 4)

We developed the PD Analysis and Instrumentation System (IMA-DP) to measure the PD in the HF band (<30 MHz) according to the technical standards IEC 60034-27 and IEEE Standard 1434-2014. We could develop the system proposed here due to the availability of suitable modular hardware components in NI’s PXI platform.

The key to development was selecting the NI PXIe-5122 digitizer that features a 20 V dynamic range, 14-bit resolution, 100 MHz sampling rate, and 40 MHz of bandwidth. The module also includes circuits for impedance matching, selectable anti-aliasing analog filters, amplifiers, and attenuators.

We added a PXIe-2593 NI Switch module (Figure 4a) to the input of the PXIe-5122 (Figure 4b-e), which can expand the system for sequential measurement of up to 16 channels, significantly reducing monitoring costs per channel. The PXIe-5122 digitizer sends the acquired raw data to the FPGA of the PXIe-7965R module (Figure 4f) for heavy processing in real time. Sending data uses the PXI Express bus over a peer-to-peer connection. Final processing and consolidation of results happens in the PXIe-8135 embedded controller (Figure 4g). Figure 5 shows the complete measurement path. Figure 6 shows the built hardware and process flow diagram.

Original Authors:

André Tomaz de Carvalho, Eletrobras Cepel

Edited by Cyth Systems

Comments